Choosing the right material for pen clips is essential for durability, performance, and style. Here's a quick breakdown of the top options:

- Stainless Steel: Durable, corrosion-resistant, and strong. Ideal for everyday use and high-performance designs.

- Brass: Offers a luxurious look with natural patina over time. Great for decorative and vintage-inspired pens.

- Phosphor Bronze: Elastic and fatigue-resistant, perfect for clips that need repeated flexing.

- Nickel Silver: Silver-like finish without tarnishing. Balances strength and flexibility.

- Aluminum: Lightweight and easy to shape. Best for prototypes or lightweight designs.

- Resin: Allows intricate designs with vibrant colors and embedded effects via 3D printing.

- Composite Materials: Combines strength and lightness. Carbon fiber stands out for modern, high-tech designs.

Each material has unique strengths and customization options, making it suitable for different pen styles and uses. Read on to discover the details and find the best fit for your design goals.

Pen Clip Materials Comparison: Strength, Formability and Customization Guide

Making A Brass and Spring Steel Pocket Clip For My Pen + More Etching w/ Aluminum Black

1. Stainless Steel

Stainless steel is a go-to material for clips, thanks to its resistance to corrosion and its ability to be strengthened through cold working. Grade 304 is the most commonly used type in this category, offering a solid mix of strength and formability, making it ideal for coil spring applications. Meanwhile, Grade 301 stands out for its ability to maintain tension over time, which is critical for long-term mechanical performance in clip designs.

Yield Strength (MPa)

The tensile yield strength of 304 stainless steel varies widely, ranging from 210 to 1,050 MPa (30,000 to 153,000 psi). This range depends on whether the material is annealed or hardened. For clips, maintaining sufficient strength is key to prevent permanent deformation. Typically, pen clips are made from stainless steel sheets around 0.020" thick, which strikes a balance between flexibility and durability, ensuring the clip doesn’t take a permanent "set" when bent.

Springiness (E/G Ratio)

The modulus of elasticity for 304 stainless steel falls between 183 and 200 GPa. However, there’s a catch: stainless steel sheets, as purchased, don’t behave like spring steel. As one expert explains:

Stainless is not a spring steel in the sheet form you buy it, it needs to be work hardened to develop spring like properties.

To achieve the necessary springiness, the material must be hammered or cold rolled, ensuring it resists permanent bending when flexed, such as over the edge of a pocket.

Customization Options

Stainless steel clips can be finished in various styles, including polished, brushed, matte, or plated surfaces. Standard color options include silver, black, and gold, though custom colors are available on request. Plating thickness typically ranges from 0.2 to 0.5 microns, offering durability. Laser cutting and engraving allow for intricate decorative designs, but it’s essential to sand and polish the edges to remove burrs and heat-affected zones. For a smooth, professional finish on custom-cut clips, vibratory tumblers with plastic beads or walnut shells are commonly used.

2. Brass

Brass is known for its striking range of colors, from golden-yellow to reddish-gold, which depends on the copper-to-zinc ratio. For instance, a 60% copper mix results in a golden tone, while an 85% copper mix gives a rich bronze appearance. Its naturally luxurious look often makes additional plating unnecessary.

However, brass isn’t just about aesthetics - it also needs to meet strict performance criteria for clip applications.

Yield Strength (MPa)

The functionality of brass is largely determined by its yield strength, which can vary widely depending on the alloy. For example, Alloy 260 (Cartridge Brass) starts at 75 MPa, Alloy 360 (Free Machining Brass) ranges from 124 to 310 MPa, and Alloy 464 (Naval Brass) reaches between 172 and 455 MPa. Since some brass grades are too soft for durable clips, work-hardening techniques like peening or adding longitudinal ribs can help clips retain their shape after repeated use.

Formability (r-value)

Brass, especially alpha brasses with more than 63% copper, is highly formable in cold working processes. Alloy C26000 (70/30 brass) strikes an excellent balance between strength and ductility, enabling the creation of complex shapes through methods like pressing, deep drawing, spinning, and bending - all without cracking. Additionally, Alloy 360 is considered the industry standard for machinability, with a perfect 100% rating, making it ideal for crafting intricate clip designs.

Customization Options

Brass clips offer plenty of finishing possibilities. They can be polished to a mirror-like shine or given a brushed texture and are compatible with gold, chrome, or rhodium plating. To preserve the polished finish and prevent oxidation, a clear lacquer coating with a tarnish inhibitor like benzotriazole can be applied. This also helps reduce the risk of skin irritation. Beyond plating, brass supports a variety of surface treatments, such as electroplating, passivation, and chemical toning, which can create shades like bronze, brown, or blue-black to further enhance its appeal.

3. Phosphor Bronze

Phosphor bronze is a standout material for pen clips due to its spring-tempered nature, which gives it excellent elasticity and fatigue resistance. This means it can endure repeated flexing without losing its grip or becoming deformed over time. Its composition - typically 85–95% copper, 4–10% tin, and 0.1–0.35% phosphorus - contributes to its hardness and resistance to wear.

Visually, phosphor bronze often ranges from a reddish-brown to golden tone, depending on its copper content and oxidation. Over time, it develops a protective patina in shades of green or dark brown when exposed to air, a feature that appeals to those crafting vintage-inspired pen designs. Mechanical Engineer Dean McClements from Xometry notes:

When polished, phosphor bronze has a lustrous golden color and offers a matte to mirror surface depending on the state of polish.

With its durability and distinctive aesthetic, phosphor bronze holds its own alongside materials like stainless steel and brass.

Yield Strength (MPa)

The yield strength of phosphor bronze varies depending on its processing. Standard grades start at 450 MPa, while cold-rolled UNS C51000 can reach up to 724 MPa, with an ultimate tensile strength of around 550 MPa.

Springiness (E/G Ratio)

Phosphor bronze has a modulus of elasticity of 110 GPa and a Poisson's ratio of 0.33, resulting in an E/G ratio of about 2.66. This makes it ideal for pen clips that need to flex repeatedly without permanent deformation. Its spring-tempered quality often eliminates the need for additional heat treatment after forming, reducing the chances of distortion during the manufacturing of intricate clip designs.

Customization Options

Phosphor bronze offers a wide range of finishing possibilities, from mirror polish to brushed matte or sandblasted textures. It can also be gold-plated for a luxurious appearance and added resistance to tarnishing. For a more weathered look, artisans use chemical treatments to create layered patinas, which are then sealed with UV-resistant clearcoats to preserve the finish. This versatility makes it a favorite for those looking to create both functional and visually striking pen clips.

4. Nickel Silver

Nickel silver is a copper–nickel–zinc alloy (50–80% copper, 5–30% nickel, 10–35% zinc) that mimics the look of silver without the hefty price tag. Unlike pure silver, it resists tarnishing and offers impressive hardness and abrasion resistance, making it a practical choice for achieving a sleek, silver-like finish. Depending on the form and quantity, prices typically range from $12 to $40 per kilogram.

This alloy strikes a balance between strength and flexibility, allowing it to bend slightly - like sliding over a shirt pocket - and then return to its original shape. However, there's a catch: excessive soldering heat can soften nickel silver, reducing its springiness. As Penturners.org member darrin1200 explains:

To much heat in the soldering softens the material causing a loss of springiness in the stainless, or softness in the visible material.

To counteract this, some pen makers combine nickel silver with a stainless steel ring tab, leveraging the alloy's aesthetic appeal while benefiting from steel's superior spring properties. This blend of mechanical and visual qualities opens the door to versatile design possibilities.

Yield Strength (MPa)

The yield strength of nickel silver varies depending on the alloy grade, making it well-suited for pen clip applications. For example:

- Standard C74500 (10–12% nickel): 200–300 MPa

- High-strength C77000 (18–20% nickel): 400–500 MPa

- C75200 grade (18% nickel): 350–450 MPa, often used for springs and industrial applications requiring extra durability.

These variations allow manufacturers to choose the right grade based on specific requirements for strength and toughness.

Customization Options

Nickel silver is highly adaptable when it comes to customization. For instance, electroplating can restore worn clips effectively, but timing is critical. A quick 5–10 minutes works best, as longer sessions can create a rough or pitted surface. As Danny Watts, author of Chronicles of a Fountain Pen, advises:

Less electroplating is better i.e. 5-10 minutes is definitely better than 2 hours.

For polishing, high-grit sandpaper (3,000 to 7,000 grit) can achieve a mirror-like finish. Additionally, nickel silver is easy to stamp, form, and machine into intricate shapes without suffering from severe work-hardening. These qualities make it a versatile material for both functional and decorative applications.

sbb-itb-1dd4fe9

5. Aluminum

Aluminum stands out as a lightweight metal with some unique finishing advantages. Weighing in at just about 30% of copper's density, it still provides the strength needed for pen clips. This makes it a practical choice for everyday carry pens. Choosing the right aluminum alloy is key: 5052 is great for formability, 6061 strikes a balance between strength and finishing quality, and 7075 offers maximum strength at 572 MPa - on par with steel or titanium.

Yield Strength (MPa)

Aluminum’s tensile strength varies significantly depending on the grade. 5052 H32 offers around 220 MPa, making it ideal for intricate bends. 6061 T6 comes in at 310 MPa, providing a versatile option for most applications. 7075 T6, with an impressive 572 MPa, boasts a strength-to-weight ratio that outperforms Grade 2 Titanium. However, its brittleness makes it unsuitable for bending. For complex clip designs, manufacturers often form aluminum in its softer, annealed state before heat-treating it to a T6 temper, ensuring the final product has the desired spring tension.

Formability (r-value)

The choice of alloy significantly impacts how well aluminum can be shaped. 5052 is the best option for intricate shapes, as its ductility allows for tight bends and press-fit fasteners without breaking. 6061 works well for moderate forming, making it a good choice for standard clip designs. 7075, however, is far too hard and brittle for bending - it will snap instead of flexing. If your design involves sharp angles or detailed curves, stick with 5052 or form the clip before heat treatment to maintain its integrity and functionality over time.

Customization Options

Aluminum offers a range of finishing options, with anodizing being one of the most popular. 6061 T6 provides the most consistent anodized finishes, ensuring even coloration across batches. In contrast, 5052 can sometimes appear blotchy, and 7075, due to its zinc content, may produce uneven or unusual hues. Anodizing allows for a broad spectrum of colors, including black, blue, red, gold, purple, orange, pink, and green. However, as Greg Paulsen, Director of Applications Engineering at Xometry, points out:

It's important to communicate any color match expectations during the quoting phase because anodizing is a pigmenting process so there is variability from batch to batch.

Other finishing techniques include powder coating, which adds scratch resistance, and tumbling, which smooths edges for a polished feel. For enhanced durability, Type III hard coat anodizing can increase surface hardness from 60-70 Rockwell B to 60-70 Rockwell C, although this limits color choices to darker tones. Laser etching is another option, offering high-contrast logos for branding purposes.

6. Resin

Resin opens up new possibilities for pen clip customization, thanks to advanced 3D printing techniques like SLA (Stereolithography). This process achieves a level of detail that traditional metalworking simply can't match. With resin printing, you can create intricate designs featuring thin walls, undercuts, and other complex geometries that would be nearly impossible to produce using metalworking methods. The precision, clarity, and smooth finishes made possible by resin make it a standout material for crafting highly detailed, custom designs.

Yield Strength (MPa)

The strength of engineering-grade resins varies significantly based on their formulation. For instance, Flexible Polyurethane (FPU) has a tensile strength of 29 MPa, making it ideal for clips that need to snap securely into place. On the other hand, Elastomeric Polyurethane (EPU) offers a lower tensile strength, ranging from 6–15 MPa, but compensates with exceptional flexibility, allowing up to 300% elongation. If durability under stress is a priority, materials like FPU or specialized "Tough" resins are excellent choices. These properties ensure that resin components maintain their structural integrity, even in highly intricate designs.

Formability (r-value)

Resin outshines metals when it comes to formability. SLA printing enables designs with incredible detail, allowing for features as small as 0.012 inches (0.3 mm) in embossing or engraving. Unlike metal, resin parts are isotropic, meaning their strength is consistent in all directions. This is due to the chemical bonding between layers during the printing process, which eliminates the grain-direction weaknesses often found in bent metal clips. Companies like Formlabs provide access to a wide range of SLA materials - over 40 options - to meet various mechanical requirements. Additionally, resin parts can be electroplated, offering the best of both worlds: intricate design freedom paired with a metallic appearance.

Customization Options

Resin isn't just about strength and precision - it also excels in creating visually stunning, personalized finishes. You can combine multiple colors to produce vibrant, multi-color effects. High-gloss finishes that resist staining or fully transparent "demonstrator" components made from materials like acrylic acetate and polyesters are also achievable. For added creativity, the label-in technique allows for encapsulating decorated or printed designs within clear resin, opening up endless graphic design possibilities without compromising structural integrity. Post-processing options such as polishing, painting, or coating further enhance the final appearance, making resin clips ready for any client or project.

7. Composite Materials

Composite materials combine the best features of different substances, making them ideal for customizing pen clips. These materials embed reinforcing fibers like carbon fiber, fiberglass, or Kevlar into a polymer matrix, creating components that are both incredibly strong and lightweight. For instance, carbon fiber composites can achieve tensile strengths up to 7,000 MPa, making them about 16 times stronger than steel while being 75% lighter. Below, we explore their performance characteristics, from strength to design flexibility.

Yield Strength (MPa)

The strength of composite materials depends on the type of fiber reinforcement and polymer matrix used. Carbon fiber composites, for example, offer exceptional tensile strength, making them perfect for clips that need to maintain their shape under constant pressure. Engineered plastics like PEEK and Ultem add another layer of performance by withstanding temperatures up to 482°F (250°C) and resisting harsh chemicals. These materials also excel in fatigue resistance, ensuring that clips remain durable and unaffected by rust, chemicals, or other wear over time.

Springiness (E/G Ratio)

The springiness of composite clips is achieved by carefully aligning fibers within the resin matrix. Carbon fiber boosts stiffness and heat resistance, while fiberglass offers a balanced mix of strength and impact resistance. Kevlar provides excellent vibration damping and shock absorption. Meanwhile, soft Nylon (PA12) delivers flexible springiness with a Shore Hardness of 70D–80D, ensuring a secure snap. For clips that need to endure repeated use, high-tensile fibers like carbon or aramid are recommended.

Formability (r-value)

Composites offer incredible flexibility in manufacturing, allowing for complex shapes and innovative designs. Advanced techniques like Carbon DLS 3D printing replicate injection molding precision while enabling intricate geometries that metals can't achieve. Other manufacturing methods include CNC machining, injection molding, and hand lay-up, each providing unique design possibilities. A standout technique, "Tube In", allows embedding unconventional materials - such as circuit boards, feathers, or even snake skins - directly into the resin matrix, creating truly distinctive pen components. For flexible joints or living hinges, consistent wall thickness (0.008–0.020 inches) and smooth fillets with a radius of 0.04–0.08 inches help prevent stress-related damage.

Customization Options

Composites open up visual and functional possibilities that metals and standard plastics can't match. Ultem, for instance, offers a striking amber transparency, while resin-based composites allow for unlimited color effects and embedded materials for luxury branding. Hybrid composites can blend natural materials like wood burls with stabilized resins, resulting in unique, hard-to-replicate patterns. For a sleek, matte finish on polymer-based composites like Delrin, fine steel wool can be used after machining. Transparent resins or clear acrylics are perfect for demonstrator styles that showcase internal mechanisms, while UV-resistant composites like ASA are ideal for outdoor use, protecting against fading and degradation. Additionally, the push for sustainability has led to the development of eco-friendly composites, including rPET, wheat straw biopolymers, and natural fiber composites made from jute, flax, or wood fibers.

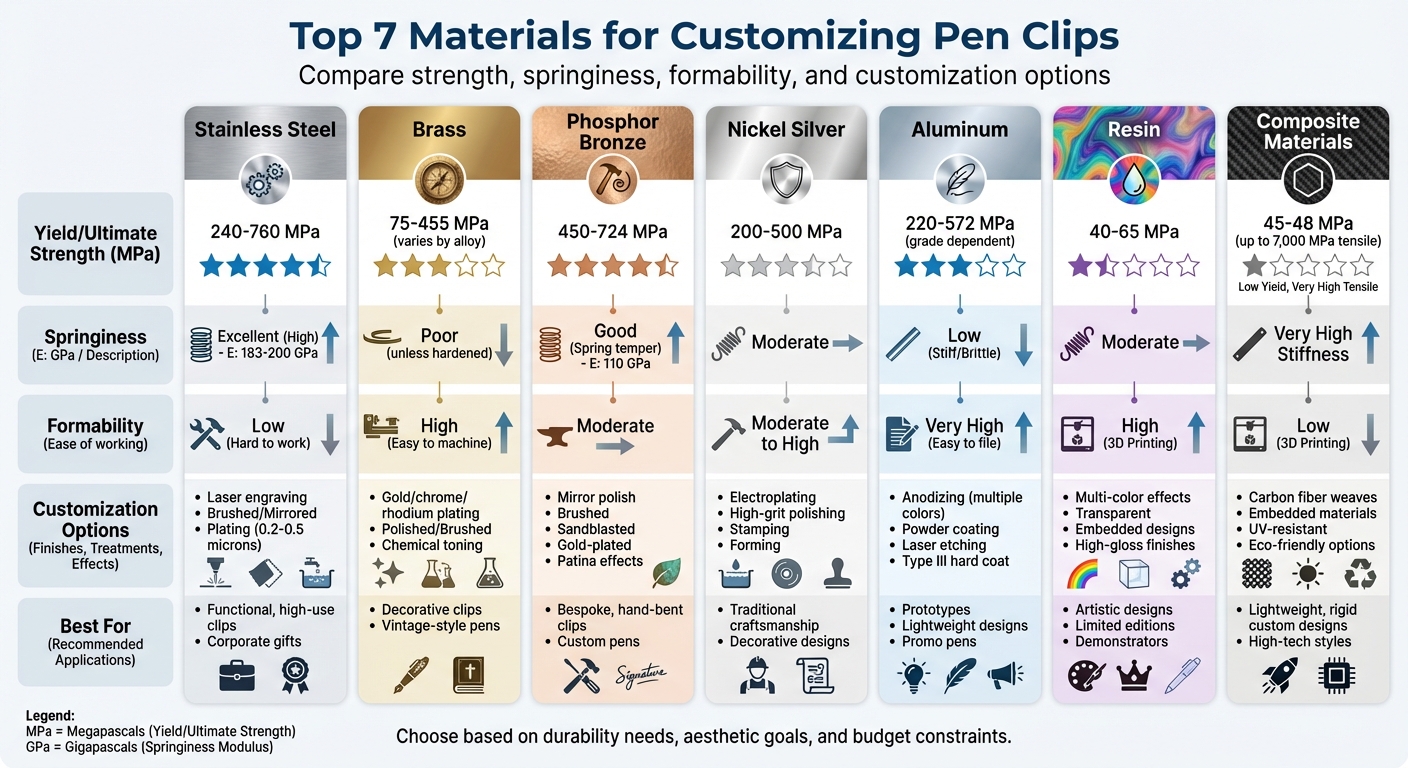

Material Comparison Table

Here’s a quick reference table summarizing the key metrics for seven materials commonly used for pen clips. It highlights their strength, flexibility, formability, and customization potential. Use this to align material properties with your design priorities.

| Material | Yield/Ultimate Strength | Springiness | Formability | Customization Options | Recommended Use |

|---|---|---|---|---|---|

| Stainless Steel | 240–760 MPa | Excellent (High) | Low (Hard to work) | Laser engraving, brushed/mirrored finishes | Functional, high-use clips; corporate gifts |

| Brass | Lower than Steel | Poor (unless hardened) | High (Easy to machine) | Laser engraving, antique finishing, patina | Decorative clips, vintage-style pens, offices |

| Phosphor Bronze | Moderate | Good (Spring temper) | Moderate | Hand-bending, traditional finishing | Bespoke, hand-bent clips for custom pens |

| Nickel Silver | Moderate | Moderate | Moderate to High | Polishing, plating, intricate detailing | Traditional craftsmanship, decorative designs |

| Aluminum | Low | Low (Stiff/Brittle) | Very High (Easy to file) | Anodizing (any color), printing | Prototypes, lightweight designs, promo pens |

| Resin | 40–65 MPa | Moderate | High (3D Printing) | Embedding materials, unlimited colors, glossy finishes | Artistic designs, limited editions, demonstrators |

| Composite (CF) | 45–48 MPa | Very High Stiffness | Low (3D Printing) | Carbon fiber weaves, modern shaping, UV-resistant | Lightweight, rigid custom designs, high-tech styles |

Stainless steel stands out for its durability and strength, making it a top choice for functional and high-use clips. However, it’s tough to work with manually and typically requires CNC machining for precision.

For prototypes or decorative designs, aluminum is a favorite due to its ease of shaping, though it lacks the durability needed for heavy daily use. Brass offers a middle ground - easy to machine but requires reinforcement to improve its springiness, such as creating a longitudinal "V" rib with a cold chisel.

Composites, like carbon fiber, excel in stiffness and modern aesthetics but have limited durability, making them ideal for lightweight, rigid designs with a high-tech vibe. Each material comes with its trade-offs, so the best choice depends on your specific design goals.

Conclusion

When choosing a pen clip material, think about durability, appearance, and budget to find the best fit for your needs.

Each material offers unique benefits tailored to different priorities. Stainless steel stands out for its unmatched durability, handling repeated flexing without losing its grip - perfect for pens you use every day. If you're aiming for a polished metal look on a tighter budget, aluminum is a solid choice, offering flexibility and anodizing options for added customization.

For those who value style, brass develops a one-of-a-kind patina over time, while resin allows for eye-catching colors and embedded designs. And if performance is your goal, carbon fiber combines incredible strength - 16 times that of steel - with a fraction of the weight, making it ideal for modern, high-performance designs.

Ultimately, the right material depends on what matters most to you: durability for daily use, standout aesthetics, or economical options for larger production runs. Refer to the comparison table above to weigh your options and make an informed decision.

Discover more creative pen designs at Fountain Pen Revolution.

FAQs

Why is stainless steel a great choice for pen clips?

Stainless steel is a popular choice for pen clips because of its strength and ability to resist wear and tear. When crafted or work-hardened correctly, it strikes a perfect balance between flexibility and sturdiness, ensuring the clip maintains its shape even after repeated use. Plus, its natural resistance to rust and corrosion makes it a reliable option for everyday use over the long term.

Why does brass develop a patina over time, and what makes it appealing?

Brass naturally forms a patina over time as it reacts with air, moisture, and even the oils from your skin. This gradual oxidation process gives the metal a distinct, aged look that many people find attractive.

The patina doesn’t just change the appearance - it adds a sense of personality and charm to brass items. This is one of the reasons why brass is a favorite for those who enjoy the classic, vintage feel it brings to pen clips and other accessories.

Why is resin a great choice for creating detailed pen clip designs?

Resin is a fantastic choice for creating detailed pen clip designs because it can be molded with incredible precision. This makes it perfect for achieving intricate features and complex shapes, ideal for crafting unique and artistic clips. Plus, its ability to deliver smooth finishes adds to its appeal.

Another advantage is how well resin pairs with advanced 3D printing techniques. This compatibility allows for the inclusion of fine details, such as textured patterns or decorative elements, giving pen clips a distinctive look while maintaining functionality.